Google Rating 4.9

SWISS ENGINEERING

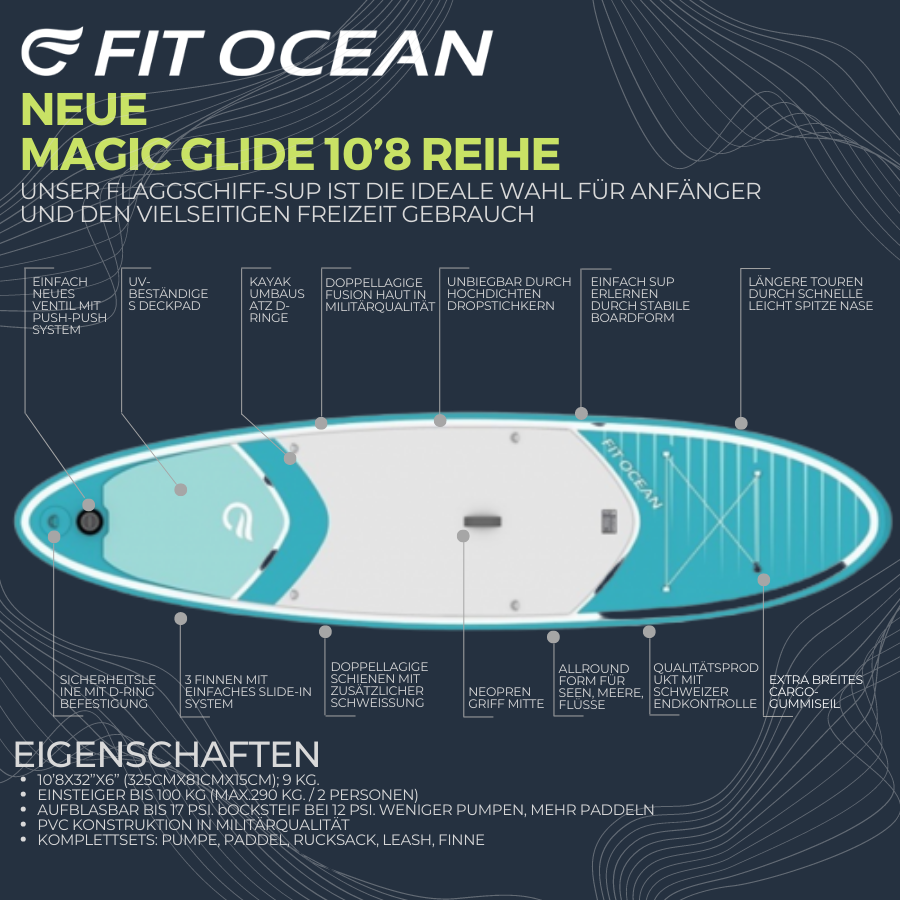

We literally live directly at the water and see all kinds of water-crafts passing by. Simple thoughts arise.. Why is the finbox not yet integrated in the hull? Why is there no displacement nose on an iSUP which looks normal? How can we make a zero-bending board in the middle section where the rider stands. Together with the top-engineers is Asia, our team riders and input from our customers we move forward.

Brushed EVA Deckpad

When: 2024

Boards applied: FIT OCEAN Magic Glide 10’8 Petrol Green; FIT OCEAN Cruise 12’6 Wood; FIT OCEAN Force 14′

The EVA deck is where you stand on. but let’s be honest, we also sit and ly and relax on it. The brushed EVA is much more comfortable to sit and ly on then cut-out structures like crocodile skin and diamond grooves. And the brushed EVA still offers more then sufficient grip for your feet while addling. After tests we discovered how to make the prefect brush into the EVA and are rolling it out over new Boards.

Hard Carbon Nose and Stringers iSUP

When: 2019, 2020, 2021, 2022, 2023, 2024 (Carbon Nose)

Boards applied: FIT OCEAN Force

Hard Carbon Displacement Nose reducing the splash of an iSUP, reducing the bow wave for a higher speed, especially in choppy waters. Hard Carbon Stringers in the middle resulting in zero bend there where the rider stands.

Finbox inside the hull of an iSUP

When: 2018, 2019, 2020

Boards applied: FIT OCEAN Ultra 14′

A problem we saw with the inflatables, was that the finbox glued on the bottom of the board, causes drag. We produced a finbox with US fin box system that can be glued inside the hull, just like with hardboards. FIT OCEAN boards are made in a premium factory that used their double chamber technology to secure air tightness. We noticed the board has a better glide, is faster, turns better and also is very stable. After 2 years testing we are now using it in our production boards. For example in the FIT OCEAN Ultra 14ft iSUP, which won in its category in the 2018 Glagla race.

ICT Hybrid Inflatable Carbon Construction

When: 2018, 2019

Boards applied: FIT OCEAN Ultra 14′ and 12’6

The Ultra 14” is made in Premium construction and additionally have a hard carbon stringer glued to the deck for extra stiffness and speed. This is hands-down the closest an inflatable can come to a composite hardboard. Because the carbon fibers are laid all in the same length-direction, you can still roll it up. This technology is licensed from Inflatable Composite™ (US Patent 8273427) and made in the USA.Left – right: The carbon material on a roll. Swiss design how to apply. Glued to the deck. Finished board rolled like a normal SUP.